Thinking topics

Some thematic information that will help you better understand Manufacturing Execution System (MES) and its implementation.

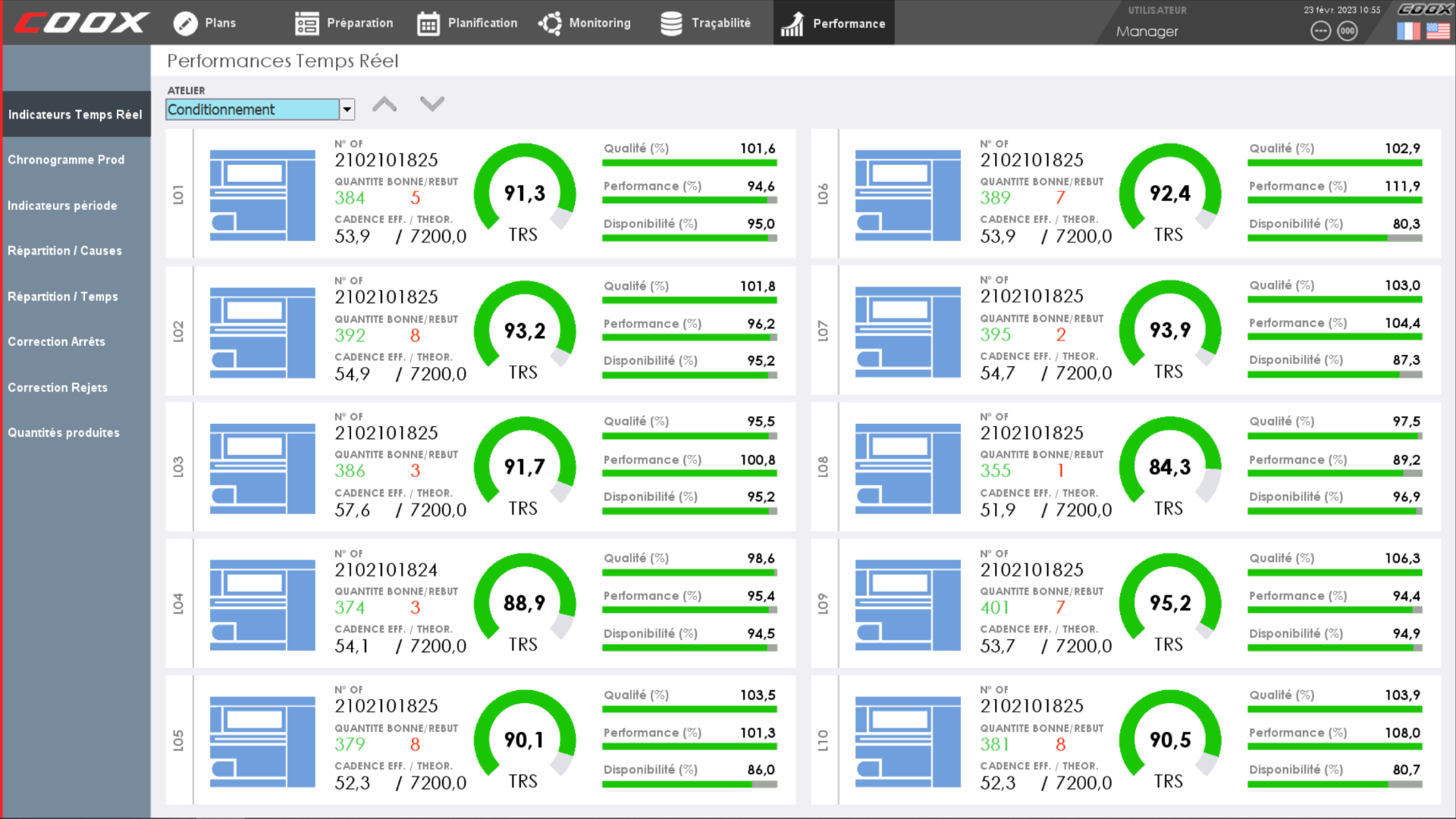

When the OEE invites itself into the MES COOX software?

What does OEE bring you? OEE (Overall Rate of Return) is certainly the best-know performance indicator in production.There are good reasons for this: with a moderate investment, it allows you to initiate a process of continuous improvement of production and reap significant gains.

IoT frees MES from the proprietary tendencies of the OEM

Often dedicated to the digitalization of factory operations, to the dispatching to the operator stations of the different tasks of the manufacturing orders from ERP and to the recording of permanence data, the MES delivers its full potential only by collecting information directly at the machine level.

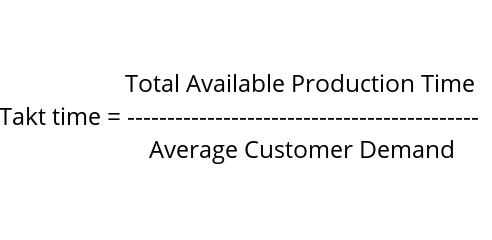

Takt Time & MES

Takt Time is a term of German origin that is generally associated with Lean Management and used in the industrial production sector. It designates the ideal duration of production of a good defined to meet exactly the customer's request. It can be expressed in seconds, minutes, hours...it all depends on customer needs.

MES, much more than just another change

With the avalanche of technologies that is now invading the industry in what is commonly called the Factory of the Future - 3D Printing, Cloud, Big data, AI, IoT, Virtual Reality, Digital Twin, etc. - there is no doubt that the industry is expected to experience many changes in the years to come.

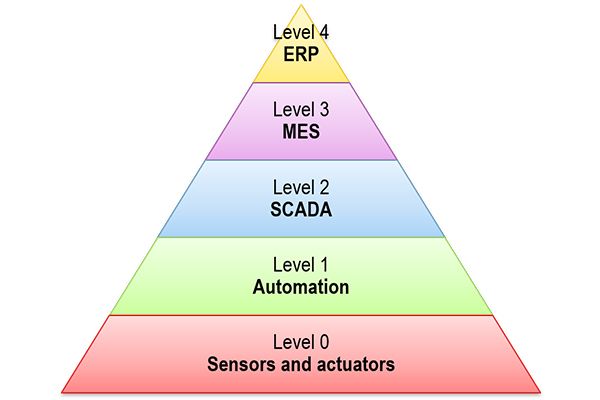

SCADA and MES: the pyramids' secret

The debate on the dividing line between ERP and MES, which indeed is variable depending on the processes and even the industrial’s choices, scarcely go beyond arbitrage duties on the management of units’ stocks and the products manufacturing recipes.

Lean Manufacturing & MES: friends or foes?

Lean Manufacturing has become very popular in recent years, as a result of the initial success of its methods in the Japanese automotive industry and a climate of fiscal restraint, where the idea of “lean” was obviously widely accepted.

With the goal of making things easier and more efficient, Lean Manufacturing was first seen as the natural enemy of heavy and expensive IT systems, a category in which the systems of the Manufacturing Execution System could be wrongly classified. But are Lean and MES really enemies?

Is the language of your industrial application important?

Starting with only a dozen or so in the early 1980s, programming languages have multiplied since then, now easily exceeding 100. There is abundant literature on the subject, which has earned its spot in large bookstores, alongside math, physics, economics, history, philosophy and the humanities.

For or against the integration of a batch engine?

Most integrators in our industry believe that integrating a batch engine results in higher costs in terms of licenses and development. Also, unless the end user requests a "batch engine" or a "ISA-88 standard", they often prefer to carry out additional specific developments, on the basis of a supervisor, in which they only use the recipe mechanism. Is it justified?

ERP & MES Cooperation

Some customers ask themselves if ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) are playing the same role. They thus challenge the opportunity to install an MES system after their ERP system has been installed. Actually MES systems have been designed to cooperate with ERP systems.

MOM vs MES (Manufacturing Operation Management / Manufacturing Execution System)

Opinions are very divided when it comes to clearly distinguishing between MES and MOM. Some think that the MES is a subset of the MOM, while others are of the opinion that they describe different functional spaces; still others think they describe exactly the same thing...

MES: Back to the Future

Born in the 1990s, the MES (manufacturing execution system) has gradually been adopted, somewhat like the ERPs that appeared in the previous decade. Put off by the budgets spent on ERPs, which they had not necessarily anticipated, companies have been more demanding when it comes to MESs, and mid-sized companies have lagged behind in adopting them.